The Greatest Guide To Sheroz Earthworks

The Greatest Guide To Sheroz Earthworks

Blog Article

Sheroz Earthworks for Dummies

Table of ContentsThe Definitive Guide to Sheroz EarthworksEverything about Sheroz Earthworks3 Easy Facts About Sheroz Earthworks ShownSheroz Earthworks Things To Know Before You BuySee This Report on Sheroz Earthworks

This system improves precision and performance by a large margin. By ensuring level ground, it makes best use of security for workers once the building procedure begins.Scraping features somewhat like dozing, but on a much finer and more precise range.

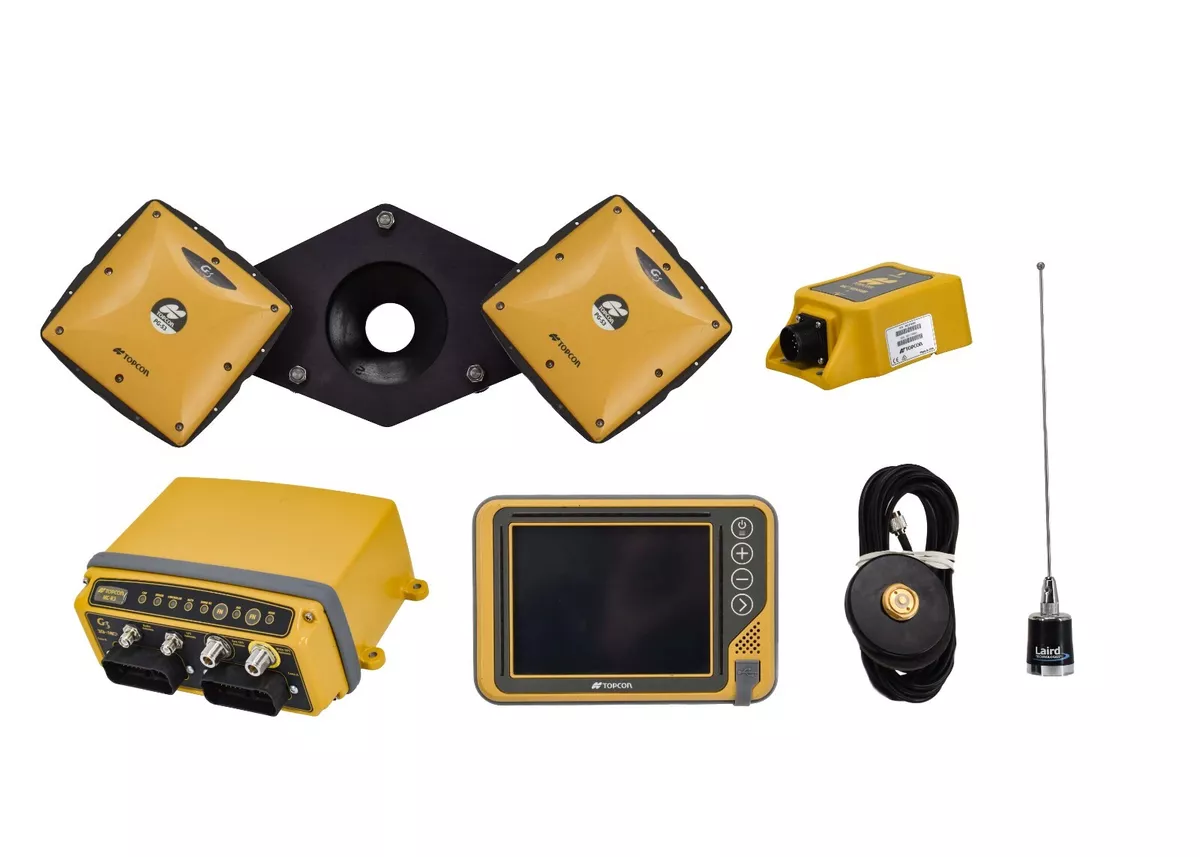

Maker control can add value to different agriculture tasks, consisting of: You can utilize the innovation to intuitively monitor and map field details in genuine time, making browsing and guiding your equipment much easier than ever. Secret attributes consist of assisted guiding that gets rid of much of the problem from the operator, water administration, return tracking and camera input.

Maker control is tough enough for hefty field use and uses the flexibility to perform multiple water drainage system applications. Attaining optimum upright accuracy is critical when rating and creating land for farming. Equipment control systems can manage this tough application promptly and effectively, enabling you to enhance efficiency and lower downtime in the area.

10 Simple Techniques For Sheroz Earthworks

Experience measurable improvements in essential areas like machine and property scheduling, fuel intake and preventative maintenance. Bolster work website safety and security and various other critical processes by boosting accuracy and reliability in crucial mining procedures. Eliminate inaccurate manual field dimensions and enhance reporting flexibility in your geotechnical and environmental tracking programs with these advanced data-capturing options.

Regardless of what the focus of your latest building and construction project is, you can profit from machine control. It can improve your leveling and sharpen your digging, and it can do it all while offering you responses on where each vagabond gets on the site at any given minute. As an overseer, you can use the system software application to see the entire website simultaneously and observe every location that is being changed in actual time.

SITECH Southwest can get you the machine control system you require to change your construction procedure (https://perpetual-streetcar-7f1.notion.site/Unlocking-Precision-with-Topcon-GPS-0c2825638577400995d3f1e51f7ea5a6?pvs=4). As an accredited Trimble dealer, we provide premier equipment for all the building refines detailed above. Just contact us today to get your machine control system!.

Sheroz Earthworks Fundamentals Explained

For this to function, rotating lasers were established to transfer signals that can be selected up by sensing units placed on dozers or . This provided drivers the standard details they required for their makers. In comparison to contemporary equipment control, these early systems were still extremely restricted at providing a complete and click this precise image and were also usually too expensive or complicated (topcon).

It is no secret that there is a lack of fresh skill going into the field. Specifically, specialists have problem attracting youngsters and, therefore, there are fewer operators entering the career. Must this pattern continue, the sector will be left with a lack of knowledgeable and trusted drivers, which implies that the top quality and efficiency of tasks will certainly be affected by a significant skills gap.

Going beyond simply supplying operators with a visual guide to bucket or blade setting, automated maker control relocates the blade to quality by speaking to the maker's hydraulics - topcon laser level. Unlike with regular equipment control, automated equipment control technology positions the obligation for accuracy and rate firmly in the hands of performance-enhancing technology

When taking a look at the present construction landscape, it is clear that, despite its substantial benefits, equipment control automation is not being embraced throughout all machines at an equal price. As a matter of fact, although automation is being accepted on equipments like graders and dozers, the uptake has been much slower for excavators, with the adoption price of automated device control on these makers still estimated at around 10% in Europe in comparison to a rate of over 50% for dozers.

Rumored Buzz on Sheroz Earthworks

Today, a boost in performance on excavators can be noted as increased accuracy and lowered over-digging being reasonably very easy to show. It is clear that the sector now needs to reassess the requirements for excavators. With the needs for performance boosting and a lack of skilled drivers, construction requires to accept the advantages that investing in automated machine control can bring.

If you are aiming to enhance your performance with today's technology we are right here to assist. Your existing personnel can be educated to perform all facets of the laid out and get tasks of the daily website requirements in a no rubbish method.

As anticipated, the excavator drivers are under a significant pressure to deliver an optimum performance while trying to accomplish their efficiency objectives at the very same time. That is why all type of help and enhancements are much more than welcome concerning enhanced accuracy and optimum production. As constantly, innovation is the key.

The Main Principles Of Sheroz Earthworks

Report this page